Volunteers at Illinois produce supplies for 200,000 COVID-19 tests

A collaborative effort at the University of Illinois to support COVID-19 testing is winding down, but not before it produced enough materials to support some 200,000 coronavirus tests across the state.

Chris Brooke (IGOH), a professor of microbiology who spearheaded the effort by faculty, graduate students, postdoctoral researchers, and laboratory workers, said that at the peak of the operation the university was producing enough viral transfer media (VTM) to support about a quarter of all COVID-19 tests in Illinois.

VTM is an essential mix of buffers, nutrients, and antimicrobials used to preserve test samples from patients until testing occurs. The university is still producing VTM for local hospitals, but the effort has scaled back significantly as campus is no longer supplying the Illinois Department of Public Health, which has arranged to receive its VTM from a commercial supplier.

The scale-back was expected, as university laboratories are not designed or intended for mass production, but contributors feel satisfaction knowing that they filled a need when health officials were desperately short on testing supplies.

“The main impact is that we played a significant role in helping the state overcome nationwide supply shortages to expand testing capacity to help combat the outbreak in Chicago and minimize additional outbreaks elsewhere in the state,” said Brooke. “This was a clear example where U of I students, postdocs, faculty, and staff stepped up and volunteered a ton of time and hard work to help save lives in the community.”

The effort launched in April, when Brooke, Marty Burke (MMG), the May and Ving Lee Professor for Chemical Innovation in the Department of Chemistry and associate dean for research at the Carle Illinois College of Medicine, and Doug Mitchell (MMG), Alumni Research Scholar Professor of Chemistry, realized that they had the basic ingredients in their own research laboratories to create VTM. Together with a pair of laboratory technicians from Burke’s laboratory, Justin Lange and Akanksh Shetty, they began creating the fluid for local testing. At the same time, Brooke and others at the university donated time and machinery to help establish a COVID-19 testing site at Carle Health.

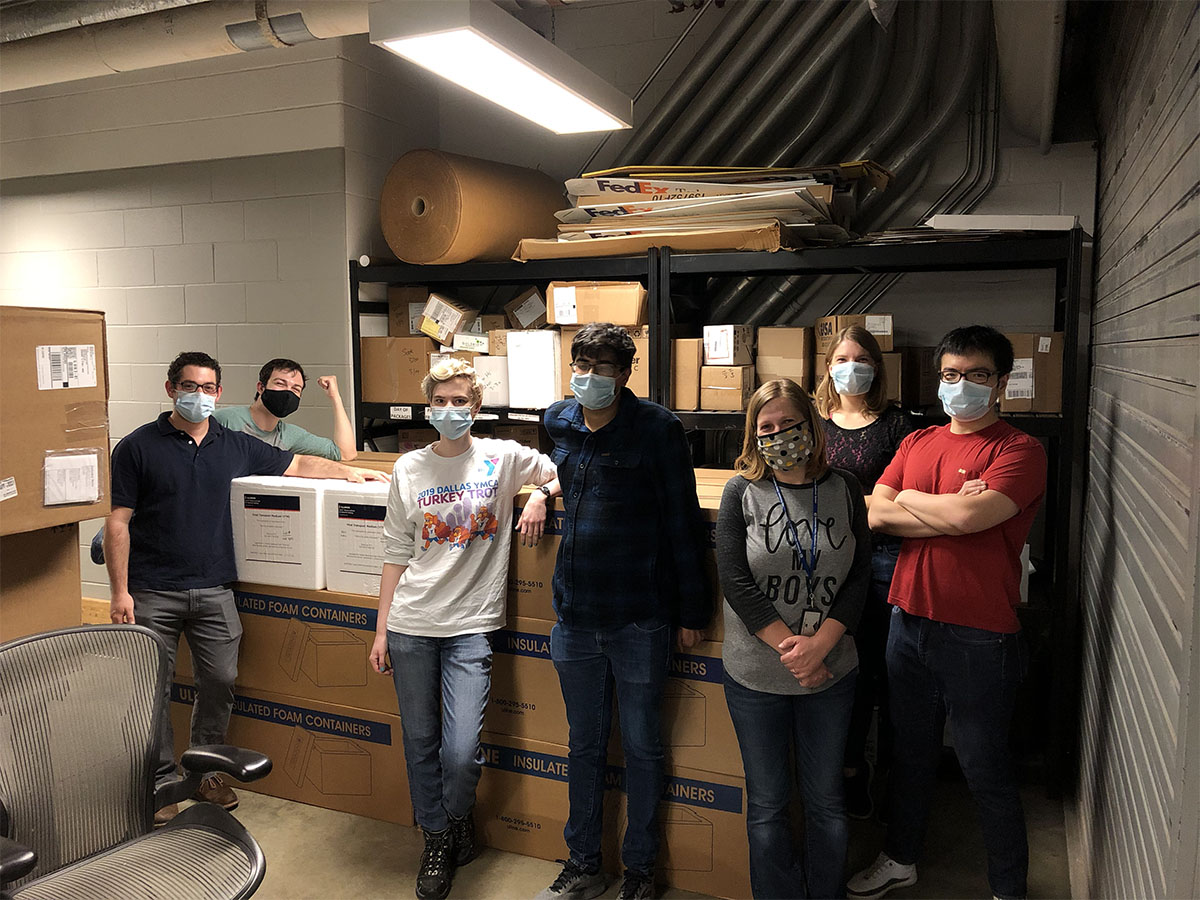

The Illinois Department of Public Health learned what they were doing and asked the university to help supply VTM for statewide testing. Organizers ramped up production, eventually drawing almost 50 volunteers into the effort. Tyler Stack, a postdoctoral researcher who coordinated the production, said that they worked out of four laboratories in the IGB.

The workers temporarily set aside their own research to create 6,000 to 8,000 vials of VTM per day. The teams often worked at sterile work stations for up to eight hours a day, filling each vial with 3 milliliters of VTM. The vials were then shipped to Springfield, Illinois.

“You uncap and recap the vials, one at a time, until we reached our daily goal of 1,100 vials, and sometimes more,” Stack said. “Unexpected blisters were often the reward for hours of uncapping and recapping these vials. The work can be monotonous, but care and attention are still necessary to ensure that the VTM is sterile and usable. Never before this experience have I emptied a gallon of water a half teaspoon at a time.”

Stack said that working outside of his own personal research projects produced a new sense of teamwork that he hadn’t experienced before.

“The only way we could produce 200,000 vials was because of the support we had for one another, and the desire to help however we could,” Stack said. “I joined because I knew that I had the skills and ability to help produce a necessary component of the COVID-19 tests and that testing is critical to save lives and get the state back to work.”