Harnessing microbial consortia to tackle plastic pollution

Plastic pollution is increasing rapidly. Every year, the world produces 390 tons of plastic, with a staggering 91% destined for incineration or landfill disposal. Consequently, plastic pollution has led to a growing array of adverse effects on the environment, wildlife, and human health.

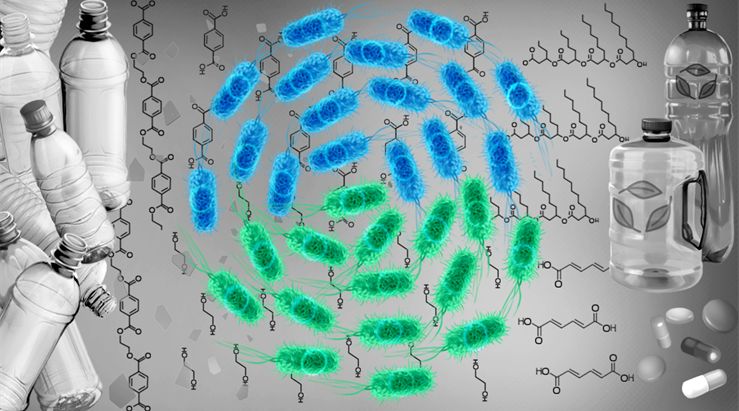

Addressing global problems like this require innovative solutions. In a recent article in Nature Communications, bioengineering professor Ting Lu (BSD/CABBI/CAIM) and his team members, Teng Bao, Yuanchao Qian and Yongping Xin, at the University of Illinois Urbana-Champaign demonstrate the potential of designer microbial communities for plastic upcycling. Their engineered system not only breaks down polyethylene terephthalate (PET), a plastic commonly found in water bottles, but also transforms it to valuable chemicals.

“Biological conversion of end-of-life plastics is tempting because of the programmability of living organisms,” Lu said. “Our study shows the utility of engineered microbial consortia in plastic upcycling, shedding light on the biological mitigation of the growing threat.”

The core concept underlying their approach is the division of labor, a form of organization through which a goal is divided into subtasks among constituting members. Such an organization is common in human society as well as in the animal kingdoms and among insects.

“We engineered a consortium of two Pseudomonas putida strains that are divided to specialize in the degradation of different substances in PET hydrolysate,” Lu said. “This ecosystem design was shown to convert the plastic into useful chemicals more effectively than single strains.”

One such chemical is polyhydroxyalkanoate, a biodegradable polymer that can serve as an eco-friendly alternative to petroleum-based plastics. The other is muconic acid, a versatile building block chemical with applications in agrochemicals, pharmaceuticals, and resins.

This method of upcycling paves the way for increased application opportunities as Lu and his team’s tailored consortia, or interacting microbial populations, could be adapted to produce different substances.

While this study focused on PET, Lu and his team remain optimistic that their findings could serve as a potential baseline for broader applications in the future. "Our work establishes a programmable, bio-based strategy to upcycle PET," Lu said. "Ultimately, together with other scientists and engineers, we aspire to make our contributions to the development of a sustainable bioeconomy."

While not everyone needs to engineer bacteria, there are small steps everyone can take to address the crisis. "Even using reusable bags and disposing of end-of-life plastics in recyclable bins can make a big difference," Lu emphasized.

The study “Engineering microbial division of labor for plastic upcycling” was published in Nature Communications and can be found at https://doi.org/10.1038/s41467-023-40777-x. This research was supported by the Future Insight Prize from Merck KGaA, and the ReSource Program of Defense Advanced Research Projects Agency.