Renewable biological catalyst carries the potential to transform wastewater into phosphorus resource

The biocatalyst developed by Wei's laboratory enables the recovery of phosphate, a vital plant nutrient, from biorefinery wastewater. / Katie Brady

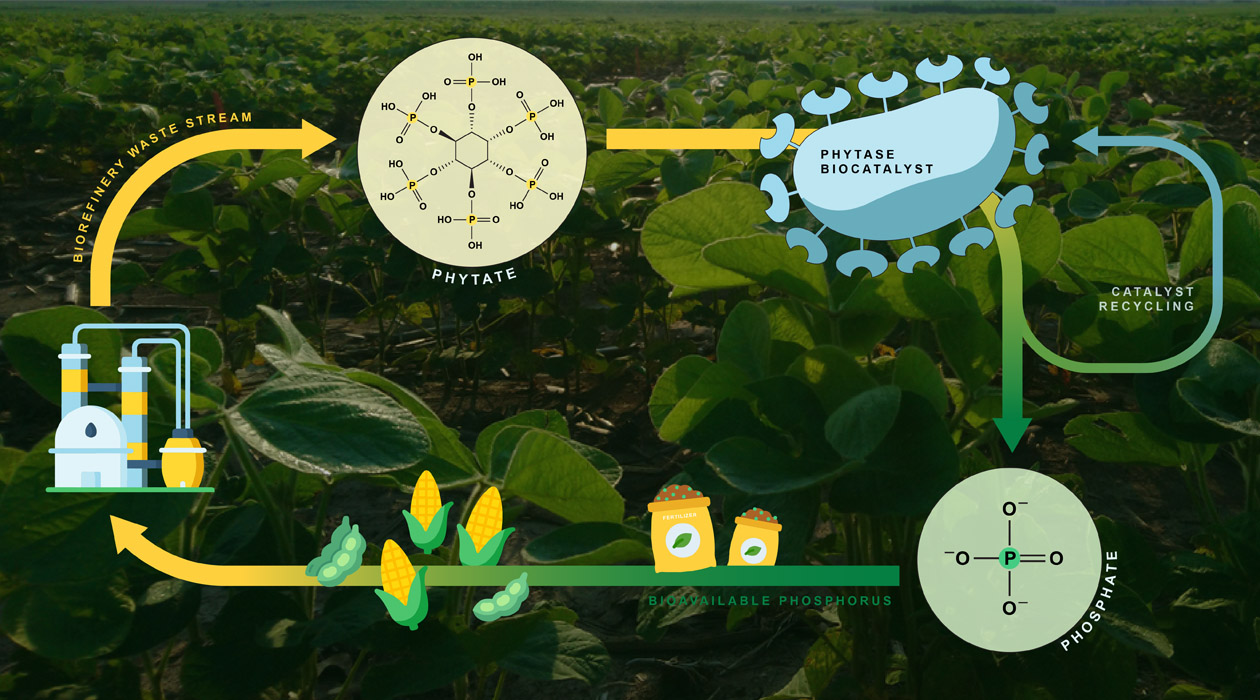

Phosphorus is an essential nutrient for plants and managing its availability is critical for growing crops to maintain the global food supply. In an effort to move toward a more sustainable bioeconomy, researchers from the Carl R. Woese Institute for Genomic Biology and collaborators have developed a new method to recycle phosphorus from the biorefinery waste stream.

The study, published in the journal Environmental Science & Technology, describes the team’s development of a process that can efficiently convert phytate—a phosphorus source that can’t be absorbed or used by plants—to bioavailable phosphate. Their approach relied on the successful use of a biocatalyst, a biological substance that speeds up a specific type of chemical reaction. The work was supported by the US Department of Agriculture.

“This study addresses a technology gap in recycling phosphorus from the biorefinery waste stream,” said Na Wei (BSD/IGOH), a professor of civil and environmental engineering at the University of Illinois Urbana-Champaign. The research was a collaboration between laboratories including Founder Professor of Agricultural and Biological Engineering Vijay Singh (CAMBERS/PFS), Professor of Food Microbiology Yong-Su Jin (BSD/CAMBERS/MME/PFS), and Professor of Civil and Environmental Engineering Ludmilla Aristilde from Northwestern University.

Historically, society has relied on nonrenewable sources of many materials, including fuels and fertilizers. Current phosphorus supplies, for example, mainly come from mining phosphate rock using a challenging and energy-intensive process that negatively impacts the environment. More recent innovations in manufacturing have explored the potential of biorefineries, facilities that convert biomass like corn or wood into fuel, animal and plant nutrients, or other useful products.

In the Midwest in particular, biorefineries for corn or soybean are a step toward a more sustainable, circular economy. Byproducts from corn and soy biorefineries represent a large but underexplored source of phosphorus.

“We focused on biorefinery waste because it typically has a lot of organic phosphorus like phytate. But phytate needs to be liberated to become bioavailable phosphorus,” Wei said.

Wei and her collaborators wanted to find an efficient way to convert phytate to phosphate, a form of phosphorus which plants can use and is common in fertilizer. Traditional processes require extensive energy or chemical inputs and can be inefficient. The researchers turned instead to a particular biocatalyst, an enzyme called phytase that can speed the chemical transformation from phytate to phosphate.

Phytase comes with its own limitations. It is time-consuming to purify and can lose its activity quickly in wastewater. To produce and protect the enzyme, the team engineered yeast cells that to display phytase on the cell surface.

“With this design, you don't need to purify the enzyme and overcome limitations for using free enzymes, such asexpensive and time-consuming protein purification, low stability, and non-reusability,” Wei said. “To produce surface display phytase biocatalyst, we just need to grow the cell in the right media and then harvest it.”

The researchers confirmed that the cell surface-displayed enzyme could efficiently convert phytate to phosphate. They also demonstrated that it remained stable after one-month storage at room temperature, retaining phytase activity. The yeast cells were able to renew catalytic activity over time by refreshing their outer membrane with fresh copies of the enzyme.

“These features enable flexible use and on-demand production of the biocatalyst for phytate conversion applications.” said Quanhui Ye, the study’s first author and a postdoctoral researcher in IGB.

The research team also used a machine learning-guided method to identify phytase variants with improved activity and robustness relative to the wild type. The biocatalyst variants were tested in wastewater from biorefineries and their performance was very promising for applications in real-world waste streams to convert organic phosphorus to bioavailable phosphate, Wei said.