In the concourse research lab of IGB, a robotic system is changing the face of synthetic biology.

Described as a one-of-a-kind “living foundry,” the system is a platform for automatic production and analysis of synthetic biological systems.

It’s called iBioFAB, which stands for Illinois Biological Foundry for Advanced Biomanufacturing, and it lies at the heart of IGB’s Biosystems Design research theme.

iBioFAB performs tasks in a fully-automated fashion driven by algorithms, making the system more reliable and opening up countless possibilities in synthetic biology research.

How the system was built and what it can be used for is representative of changes occurring in the field of synthetic biology — changes that require more automation and standardization so that tasks such as DNA synthesis, pathway optimization, and genome engineering can be done efficiently and at a low cost.

iBioFAB was built with these changes in mind. As a result, the system could become as transformative of a technology as the computer, according to chemical and biomolecular engineering graduate student Ran Chao, who has worked with the system since it was created.

“I think building iBioFAB is an important step to really push the biotech industry forward,” he said.

The system was built at the same time the Biosystems Design theme was being formed at the IGB. The two go hand in hand, as they are both at the forefront of changes in synthetic biology.

Synthetic biology, a field that has advanced in the last two decades, is a fusion of engineering and biology, and can involve creating new biological systems or redesigning existing ones.

This could mean anything from designing new proteins to engineering microbes that perform specific biological functions.

At IGB, researchers see synthetic biology as an approach to solving problems in health and sustainability. Research could improve drug production, increase the efficiency of photosynthesis and alter the protein content of food crops.

But some of these pursuits would require technologies that don’t yet exist.

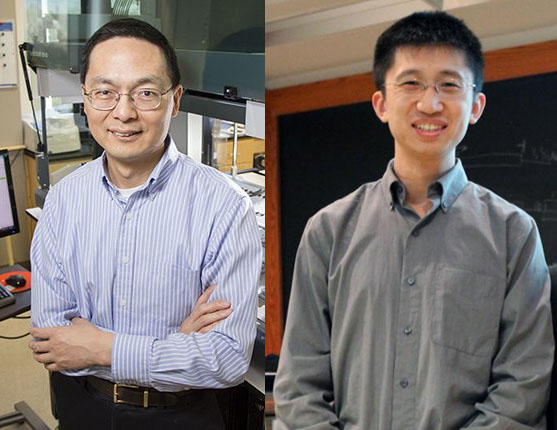

One of the theme’s goals is to create these technologies, and this vision was in mind when iBioFAB was being brought to life by Steven L. Miller Chair of Chemical and Biomolecular Engineering Huimin Zhao, the Biosystems Design theme leader, and Professor of Chemical and Biomolecular Engineering and fellow Biosystems Design member Christopher Rao.

“Back then we were thinking, where do we think synthetic biology is going to go?” Chao said.

One of the fundamental obstacles they saw was that much of the work is handled by human hands. Because the work is repetitive, mechanical and labor intensive, it can involve many human errors and biases.

So they decided to carry out these processes with robotics as much as possible.

“Given the tremendous amount of genetic information we have to go through, and all these different designs we have to come up with, it’s better to use machines,” Chao said.

Many fields have already turned to automation, but several factors make synthetic biology’s transition different.

First, it’s unpredictable, so an automated system that’s producing synthetic biological systems has to be versatile to take this unpredictability into account.

In the pharmaceutical industry, for example, similar automated systems are used for only one task. But in synthetic biology, researchers could be using the system to work on one project one day, and another project the next day.

Secondly, the workflows in synthetic biology are complex.

“There are many more steps involved,” Chao said. “And there are many more steps that can fail in the process.”

They realized they needed to take these differences into account and make the system adaptable, programmable and modular.

iBioFAB’s modularity — meaning that it’s made up of different modules that share the same standard — is what makes it unique.

Modularity is a fundamental principle of synthetic biology, Zhao said, but it’s easier said than done.

“Right now it’s really hard to apply (modularization) to the engineering of most biosystems,” Zhao said.

Others in academia or industry often take a different approach to address the automation challenge in synthetic biology, according to Zhao.

“Another school of thought is to establish a partially automated system in which only certain steps are automated while a human researcher is still transferring samples within the system and driving the entire process,” he said.

iBioFAB is different because it is a fully integrated system driven by algorithms, with its functions executed by a robotic arm.

“What we think is going to be the future is taking the human out of that part of the research,” Chao said. “It’s not as reliable. You will still make a mistake when you’re transferring a sample from one step to another or deciding what to do next.”

Using algorithms allows the process to be easily repeated, and it also makes it easier to find where things went wrong in an experiment.

“When you make a mistake, a human researcher, we don’t know where it went wrong, usually,” Chao said. “We say everything is documented on lab notebooks, but the reality is you don’t even know what happened when you work on it.”

Some mistakes go undetected, which could lead to the experiment having a largely different outcome.

“You don’t want to have this kind of uncertainty, because that will really increase how long it takes to develop a biosystem, and also how much it’s going to cost to finish it,” Chao said.

The reliability that iBioFAB provides could help ease concerns that some may have about synthetic biology.

“Previously, people are very hesitant to invest in biotechnology or especially synthetic biology, since we’re doing things in a different scale. We’re not only testing; we’re also building new biosystems. That’s pretty risky,” Chao said. “But to de-risk that, you want to improve the tools available in this field.”

One improvement is that iBioFAB can handle more complex systems, which is important in data-rich synthetic biology.

“When a human is driving an experiment, you have to understand the data set,” Chao said. “But when we go beyond a certain number of dimensions, the human mind starts to struggle.”

For example, when researchers study a genome, they’re analyzing thousands of genes.

“If every gene has three variants, that’s a huge combination of possibilities,” he said. “It would be very difficult for us to keep track.”

But an algorithm can keep track. One of the first projects iBioFAB was a part of involved a yeast genome, which has approximately 6,000 genes (DOI: 10.1038/ncomms15187). The researchers showed the system could be used to automate the genome-scale engineering workflow of this genome.

Though automation is becoming the new normal in synthetic biology, this doesn’t necessarily mean that humans will be completely out of the picture.

“I think what we should do is put a human researcher into the design role instead of a driving role,” Chao said. “They will be coming up with new algorithms or a game plan of the engineering and the fundamental research, then let the machine play the game with the biosystem.”

This will allow researchers to study more complex systems.

“It’s like an extension of the human mind that goes beyond a normal capability of what we can think,” Chao said.

Many other fields — such as software or mechanical engineering — are heading in this direction, and using artificial intelligence to extend human capabilities.

Now, Chao believes it’s synthetic biology’s turn.

“Personally, I think automation will be the trend, no matter which industry you’re talking about,” he said. “There is a lot of work that should be handled by automation technology, not by a human. You just can’t compete with machines.”

In Chao’s opinion, this makes the potential for synthetic biology and those working in the field even greater.

“What people should really focus on is how they can adapt themselves to work with machines or even generate a new industry,” he said.

Chao predicts that a robotic system like iBioFAB could be a technology as transformative as computers.

Computers changed the way calculations were made, the way problems were solved — and this created an entirely new industry.

“No matter if you’re a biologist or a bioinformatician or computer scientist, you can just use your creativity and intelligence to design algorithms or come up with biosystems of interest,” Chao said. “Then we can use this platform as a tool to run the algorithms, test the biosystem, and generate data or engineer these systems for useful purposes. And that will create a new industry, I would say.”

Chao believes systems like these will also elevate research and the capabilities of researchers.

Zhao is most excited to see advances in drug discovery and metabolic engineering, which involves engineering a microorganism to produce a particular chemical.

Sometimes, this can take years to accomplish, but with a technology like iBioFAB, Zhao said the time could be reduced to one year.

“For metabolic engineering, I think the goal will be even higher and the impact would be even bigger,” he said.

At the IGB, iBioFAB has even fueled entrepreneurial pursuits.

“In the past few years, I have been trying hard to encourage my students to be more entrepreneurial and start companies to commercialize the synthetic biology technologies developed in my laboratory,” Zhao said. “I try to expose them to the business side.”

Zhao argues that synthetic biology can make more of a difference if it’s used in industry.

“Synthetic biology is very applied, and there are many opportunities to start companies,” he said. “It doesn’t make sense for us to just publish papers. If you really want to have impact, then commercialization is probably the more direct impact.”

Zhao assisted Chao and a group of Ph.D. students in starting a company called LifeFoundry, which will specialize in using biofoundry technology to rapidly prototype biosystems for industrial applications.

They recently opened a space in Research Park at the University of Illinois, where they hope to build the next generation of the foundry that will allow for more flexibility and human and robot interaction.

Several companies from a range of industries have expressed interest in working with them.

“We believe there’s a huge potential around this platform. It’s an enabling tool,” Chao said. “In either academia or industry, it helps researchers conduct research in a different way.”