The Illinois Biological Foundry for Advanced Biomanufacturing (iBioFAB)

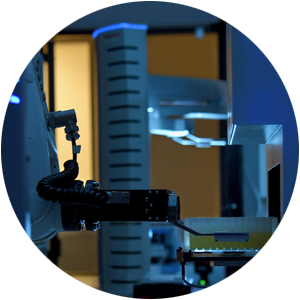

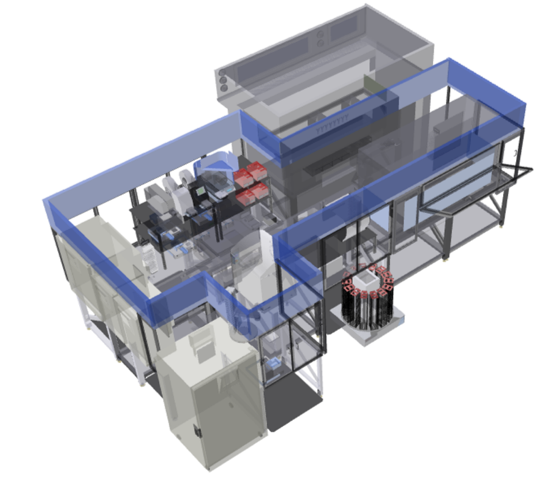

The iBioFAB aims to accelerate the biological engineering process by integrating artificial intelligence/machine learning with automation. This synthetic biology foundry features a 6-degree-freedom articulated robotic arm that travels along a 5-meter-long track to transfer microplates among more than 20 instruments installed on the platform.

The iBioFAB aims to accelerate the biological engineering process by integrating artificial intelligence/machine learning with automation. This synthetic biology foundry features a 6-degree-freedom articulated robotic arm that travels along a 5-meter-long track to transfer microplates among more than 20 instruments installed on the platform.

The system houses three liquid handling devices: the nanoliter-scale Labcyte Echo 550 acoustic liquid handler in addition to the pipet-based Tecan Freedom EVO 200 and Tecan Fluent 1080 systems. The iBioFAB Tecan Fluent is equipped as a workhorse for most cell-culture related tasks, containing a SciRobotics Pickolo colony picker and PetriPlater spiral plater in addition to a vacuum-based solid phase extraction platform and an array of Peltier blocks and bioshakers. For sample analysis, the iBioFAB includes a BioTek Cytation 5 automated microscope, a Tecan Infinite M1000 plate reader, and an Agilent Fragment Analyzer Infinity. To enable unattended automated operation, the iBioFAB also contains instruments for automating standard laboratory tasks: An Agilent Microplate Centrifuge, Agilent Microplate Barcode Labeler, four Thermo-Fisher Multidrop Combi reagent dispensers, four Biometra TRobot thermal cyclers, a Thermo-Fisher ALPS 3000 automated microplate heat sealer, a Brooks Life Sciences XPeel plate seal remover, as well as multiple plate shaker and Peltier block arrays.

At maximum capacity, this biofoundry can house over 500 96-well plates within its four Thermo-Fisher Cytomat automated incubators. Coupled with an integrated laboratory information management system (LIMS) and scheduling software, the iBioFAB can generate thousands of output samples each day using custom-designed workflows for plasmid assembly, microbial transformations, and more.

Publications

Towards a fully automated algorithm driven platform for biosystems design

2019

HamediRad, M., Chao, R., Weisberg, S., Lian, J., Sinha, S., & Zhao, H. (2019). Nature Communications, 10:5150.

Building a Global Alliance of Biofoundries

2019

Hillson, M. Caddick, …, H. Zhao, P.S. Freemont. (2019). Nature Communications, 10:2040.

Biosystems design by directed evolution

2019

Wang, Y., Yu, X., & Zhao, H. (2019). AIChE Journal. 66, e16716.

Automated multiplex genome-scale engineering in yeast

2017

Si, T., Chao, R., Min, Y., Wu, Y., Ren, W., & Zhao, H. (2017). Nature Communications, 8, 15187.

Fully automated one-step synthesis of single-transcript TALEN pairs using a biological foundry

2017

Chao, R., Liang, J., Tasan, I., Si, T., Ju, L., & Zhao, H. (2017). ACS Synthetic Biology, 6(4), 678-685.

Engineering biological systems using automated biofoundries

2017

Chao, R., Mishra, S., Si, T., & Zhao, H. (2017). Metabolic Engineering, 42, 98-108.

FairyTALE: a high-throughput TAL effector synthesis platform

2013

Liang, J., Chao, R., Abil, Z., Bao, Z., & Zhao, H. (2013). ACS Synthetic Biology, 3(2), 67-73.